Silica Gel Desiccants are a crucial component in maintaining the quality and shelf-life of various products during storage and transportation. Understanding the importance of these moisture-absorbing agents is key to preserving goods in optimal conditions. In this guide, we will explore the factors to consider when choosing the best silica desiccants, the different types available, tips for storage and usage, benefits in various industries, common mistakes to avoid, and frequently asked questions to help you make informed decisions.

Understanding the Importance of Gel Desiccants

Gel desiccants play a crucial role in preventing moisture-related damage to products during storage and transportation. They are essential for maintaining the quality and shelf-life of various items, such as electronics, leather goods, and medications.

The ability of gel desiccants to absorb and hold moisture makes them a reliable solution for preserving goods in optimal conditions.

Factors to Consider when Selecting Gel Desiccants

When selecting gel desiccants for your storage requirements, it is crucial to consider a variety of key factors to guarantee the most effective moisture control. By taking the following aspects into account, you can ensure that your stored items remain in optimal condition for an extended period of time:

- Humidity Levels: One of the most important factors to consider when choosing gel desiccants is the relative humidity levels in the storage environment. Different types of gel desiccants are designed to absorb varying levels of moisture, so it is essential to select the right product based on the humidity levels in your specific storage area.

- Absorption Capacity: Another critical factor to take into account is the absorption capacity of the gel desiccants. The absorption capacity determines how much moisture the desiccants can effectively absorb before needing to be replaced or regenerated. It is important to choose desiccants with a high absorption capacity to ensure maximum moisture control.

- Size and Quantity: The size and quantity of gel desiccants needed for your storage requirements will depend on the size of the storage area and the amount of moisture present. It is important to calculate the correct amount of desiccants needed to effectively control moisture levels in your storage space.

- Regeneration: Some gel desiccants can be regenerated and reused multiple times, while others are disposable and need to be replaced once they reach their absorption capacity. Consider whether you prefer reusable desiccants that can be regenerated or disposable desiccants that need to be replaced regularly.

- Packaging: The packaging of gel desiccants can also impact their effectiveness. Look for desiccants that are packaged in breathable materials to allow for proper air circulation and moisture absorption. Proper packaging can help ensure that the desiccants remain effective for longer periods of time.

By considering these key factors when selecting gel desiccants for your storage needs, you can ensure that your stored items are protected from moisture damage and remain in optimal condition.

1. Size and Weight of Items

Consider the size and weight of the items you intend to protect from moisture. This will help determine the appropriate size and quantity of gel desiccants needed for efficient absorption.

2. Humidity Levels

Assess the humidity levels in your storage environment. Higher humidity levels will require desiccants with greater absorption capacities to effectively control moisture.

3. Packaging Requirements

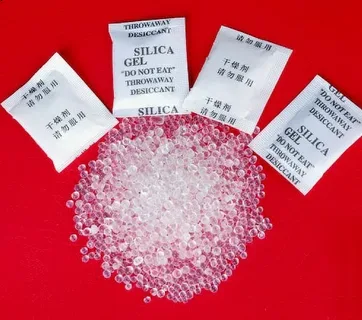

Consider the packaging requirements of your items and the application method of the desiccants. Choose between loose desiccant beads, packets, or canisters based on the ease of use and distribution within your storage containers.

Different Types of Gel Desiccants Available

Different Types of Gel Desiccants Available

Gel desiccants are commonly used in a wide range of applications due to their ability to absorb moisture effectively. They come in various forms, such as indicating and non-indicating types, to cater to different needs and preferences. Indicating gel desiccants change color to indicate when they are saturated with moisture, making them ideal for applications where monitoring humidity levels is important. On the other hand, non-indicating gel desiccants do not change color and are often used in situations where visual indication of saturation is not necessary. Whether you need to protect electronics, pharmaceuticals, or food products from moisture damage, there is a gel desiccant suitable for your specific application.

Indicating Silica Gel

Indicating silica gel is a highly useful desiccant that changes color when it becomes saturated with moisture, making it a convenient and easy way to determine when it needs to be replaced. This feature is especially beneficial for applications where visual inspection of moisture saturation is crucial for maintaining the effectiveness of the desiccant. By providing a clear indication of when the silica gel has reached its capacity, users can ensure that their products or equipment are protected from moisture damage. In addition, the color-changing properties of indicating silica gel make it a popular choice for a wide range of industries and applications that require precise monitoring and control of moisture levels.

Non-Indicating Silica Gel

Non-indicating silica gel is suitable for long-term use as it does not rely on color changes to indicate moisture saturation. This type of desiccant is preferred for applications where continuous moisture control is needed without the need for visual indicators.

Tips for Proper Storage and Usage of Silica Gel Desiccants

When it comes to effectively utilizing Silica Gel Desiccants, it is important to understand the importance of proper storage and usage in order to maintain their moisture-absorbing capabilities over time. By following these tips, you can ensure that you are getting the most out of your gel desiccants and maximizing their performance.

- Store in Airtight Containers: To ensure the longevity of your gel desiccants, store them in airtight containers when not in use. This helps prevent them from absorbing moisture from the environment prematurely.

- Avoid Extreme Conditions: Keep gel desiccants away from high temperatures or direct sunlight, as these can reduce their effectiveness in absorbing moisture. Choose a cool, dry place for storage.

- Regular Replacement: It is important to replace saturated gel desiccants regularly to maintain optimal moisture control. Once they become fully saturated, they will no longer be able to absorb additional moisture.

By following these simple tips, you can ensure that your gel desiccants remain reliable and effective in preserving the quality of your stored items.

Benefits of Using Gel Desiccants in Various Industries

Gel desiccants play a crucial role in multiple industries due to their exceptional moisture-absorbing properties. Here are some key benefits of using gel desiccants:

1. Pharmaceuticals

- Preserves the effectiveness and integrity of medications by controlling humidity levels.

- Prevents degradation of pharmaceutical products due to moisture exposure.

- Extending the shelf-life of medicines and medical supplies is crucial in ensuring that these essential items remain effective and safe for use. By implementing proper storage and preservation techniques, healthcare providers can help maintain the quality and potency of drugs, vaccines, and other medical products for longer periods of time. This not only helps in reducing waste and costs associated with expired medications but also ensures that patients receive the full benefits of the treatments they are prescribed. Additionally, extending the shelf-life of medical supplies can also improve access to healthcare in remote or underserved areas where resources may be limited. By prioritizing the longevity of medicines and medical supplies, healthcare systems can better serve their communities and promote overall health and well-being.

2. Electronics

- Protects electronic components and devices from moisture damage, ensuring optimal performance.

- Prevents corrosion and short circuits caused by humidity in electronic equipment.

- By increasing the longevity and reliability of electronic products, manufacturers can ensure that consumers are getting the most out of their investments. This not only benefits the consumer by providing them with products that last longer and perform better, but it also helps to reduce electronic waste by extending the lifespan of devices. Additionally, improved longevity and reliability can lead to cost savings for both consumers and manufacturers, as they may not need to replace products as frequently or deal with costly repairs. Overall, prioritizing longevity and reliability in electronic products is a win-win situation for all parties involved.

3. Food Packaging

- Keeps food products dry and fresh during storage and transportation.

- Prevents the growth of mold, mildew, and bacteria in food packaging.

- Reduces spoilage and extends the shelf-life of perishable items.

Gel desiccants are a crucial component in a wide range of industries, serving as a key element in ensuring the quality, safety, and longevity of various products. From pharmaceuticals to electronics, these industries rely on gel desiccants to protect their products from moisture and humidity, ultimately preserving their integrity and extending their shelf life. By investing in gel desiccants, businesses can uphold high standards and enhance customer satisfaction, ultimately solidifying their reputation as a reliable and trustworthy supplier. In today’s competitive market, where consumer expectations are higher than ever, the use of gel desiccants is not just a cost-effective solution, but a strategic investment in the future success of a business.

Common Mistakes to Avoid When Using Gel Desiccants

When using gel desiccants, it is important to be aware of common mistakes that can impact their effectiveness. Here are some key pitfalls to avoid:

- Avoid placing gel desiccants directly in contact with items: Direct contact with desiccants can lead to abrasion or leakage, potentially damaging the items they are meant to protect. Always use a barrier between the desiccants and your belongings.

- Do not reuse saturated gel desiccants: Once a desiccant reaches its saturation point, it loses its ability to absorb moisture effectively. Make sure to replace saturated desiccants with fresh ones to maintain optimal moisture control.

- Be cautious of using gel desiccants near food items: Gel desiccants are not food-safe and can be harmful if ingested. Keep them away from food products and ensure they are not accidentally consumed.

Conclusion

In conclusion, choosing the best silica gel desiccants is crucial for preserving the quality and shelf-life of your stored goods. By considering factors such as size, absorption capacity, and packaging requirements, you can select the most suitable desiccants for your needs. Proper storage and usage of gel desiccants can help maintain their effectiveness and ensure optimal moisture control. Industries across various sectors rely on gel desiccants to prevent moisture-related damage and extend the lifespan of their products. By avoiding common mistakes and following best practices, you can make the most out of your gel desiccants and reap the benefits they offer.

FAQ’s

What is the lifespan of silica gel desiccants? How often should they be replaced?

The lifespan of gel desiccants varies depending on the level of humidity they are exposed to and the size of the desiccant. In general, gel desiccants can last anywhere from a few weeks to a few months. It is recommended to replace them once they become saturated and are no longer able to absorb moisture effectively.

Can gel desiccants be recycled or disposed of safely?

Gel desiccants can be recycled by drying them out either in an oven or microwave to remove the absorbed moisture. Once they are dry, they can be reused. However, if the desiccants are damaged or reach the end of their useful life, they can be disposed of safely in the regular household waste as they are non-toxic.

Are there any safety precautions to consider when handling gel desiccants?

When handling gel desiccants, it is important to avoid direct contact with skin or eyes as they can cause irritation. In case of contact, wash the affected area with plenty of water. Additionally, do not ingest the desiccant beads as they are not meant for consumption. Keep gel desiccants out of reach of children and pets to prevent accidental ingestion.

| Other Good Articles to Read |

| Blogs-Nation |

| Blogs-Peoples |

| Bryan Smith Blogs |

| intellect blogs |

| the fault in our blogs |

| blogs eu |

| oz forums |

| recruitment blogs |

| zet blogs |

| id blogs |

| Blog Studio legale |

| blogs map |